Dental Thermoformıng Technologıes

Engineered Layers for Every Dental Application

Every Kalivon sheet is designed with precision extrusion technology from single-layer PETG to multi-layer hybrid structures, optimized for clarity, durability, and patient comfort.

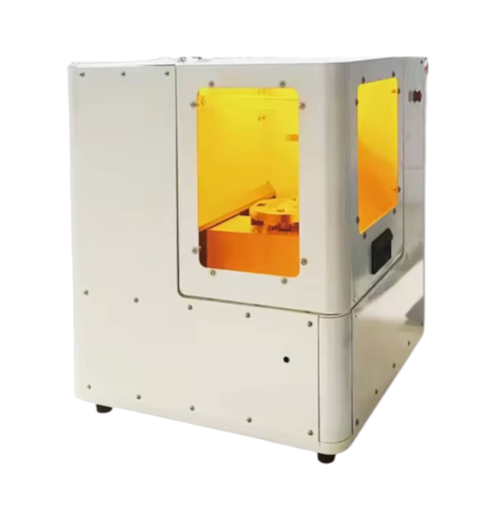

THERMOFORMING MACHINE V1

Pressure Forming Machine for Dental Appliances

Pressure forming unlike vacuum forming produced parts with complex shapes and details, and tight tolerances. Pressure forming also supports clean lines, tight corners, and other intricate details. CNC routing or robotic routing is used for parts finishing.

Kalivon P-100 Pressure forming machine is ideal for making clear aligners. This product uses air, unlike conventional products, does not generate noise during operation.

- Manufacturer warranty of 1 year

- Suitable for various thicknesses 0.5mm to 4.0mm

- (127mm, 125mm, 120mm) Square and round sheet can be used.

TRIMMING ROBOT V1

Delivers unmatched edge accuracy and surface finish for PETG, TPU, and multi-layer dental sheets.

HIGH PRECISION

The trimming robot has high precision and can control the error within ± 0.05mm. It can accurately cut according to the setting, and the cutting surface is smooth, flat, and complex curves and fine angles can be accurately presented. If cutting 1mm thick material with a deviation of less than 0.05mm, it can improve the quality and comfort of the dental arch, and the edges only need a little polishing.

WIDE APPLICATION

The trimming robot has excellent processing materials. No material restrictions, capable of processing all organic dental sheets. It can handle sheets of different thicknesses from 0.1mm to 2mm, and can be processed with stable performance and excellent precision even in ultra-thin and thicker layers, providing a wide range of solutions for the dental industry.

- Manufacturer warranty of 1 year

- Suitable for various thicknesses 0.1 mm to 2.0mm

- Spindle speed Max 30,000 rpm

- Size:460mm*400mm*400mm

FAQ

Frequently Asked Question?

Is the material clinically proven and biocompatible for use in the oral environment?

Kalivon Elit sheets has successfully passed biocompatibility evaluations, including Skin Sensitization, In vitro Cytotoxicity, and Skin Irritation tests, key regulatory requirements for demonstrating the preclinical safety of medical devices.

What are the advantages of Kalivon Elit PETG compared to conventional materials used by other brands in thermoforming?

The sheet provides crystal-clear transparency with minimal haze, allowing better aesthetic outcomes and visual inspection of fit and finish.

Kalivon Elit maintains exceptional toughness and flexibility, reducing the risk of cracks or stress marks during thermoforming and trimming.

Unlike standard PET, PETG retains its shape and strength even under extended heat and pressure cycles, ensuring consistent performance across batches.

What is the shelf life of Kalivon Mono Layer, Dual Layer or Tri Layer Sheets?

Under proper storage conditions and unopened vacuum packaging, the product retains full performance for three (3) years.

What types of dental materials can be used with the Kalivon Dental Forming Machine?

PETG, TPU, Tri Layer(PETG/TPU/PETG) and EVA. Suitable for various thicknesses 0.5mm to 4.0mm (127mm, 125mm, 120mm) Square and round sheet can be used.

How does the temperature and pressure control system ensure accurate thermoforming results?

An integrated PID temperature controller regulates the heating plate to achieve optimal softening of the thermoplastic sheet without overheating or uneven deformation. Simultaneously, the vacuum and pressure calibration system guarantees uniform material adaptation over the dental model, minimizing air pockets, wrinkles, or thickness variations.

Can the trimming parameters be customized for different aligner or retainer thicknesses?

Yes. The Kalivon Trimming Machine allows full customization of cutting speed, spindle rotation, and tool path to match different aligner and retainer thicknesses.

Users can easily adjust parameters through the digital control interface, selecting optimal settings for various materials such as PETG, TPU, EVA or multilayer composites. This flexibility ensures precise edge finishing, prevents material chipping, and maintains consistent trimming quality across different sheet thicknesses and designs.